Latest News

New Zealand Coastal Building Exterior

20 April 2025

Low Urban Pollution Exposure

High Coastal Salt Exposure

Wellington is New Zealand’s capital, cultural center, and a haven for nature enthusiasts. Most of the city is located on a narrow 2 km (1.2 mile) wide strip of land between a beautiful ocean harbor and rolling green hills. This lovely city has a mild climate with regular heavy rain and low urban pollution levels.

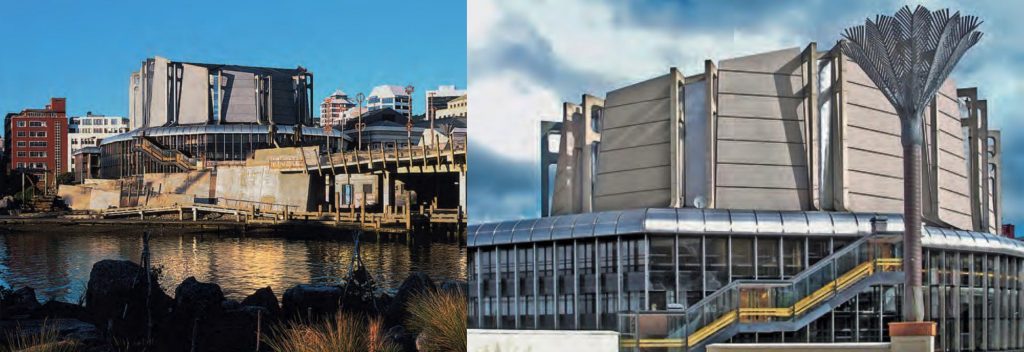

Completed in 1983, Wellington Convention Centre (WCC) adjoins the harbor. It was designed by the architecture firm Warren and Mahoney. Figure A shows its original appearance. A corrosion study of New Zealand identified Wellington as having a very corrosive environment. The building’s location on the harbor further increases salt (chloride) exposure. The architect used concrete and Type 316 (UNS S31600, EN 1.4401, SUS 316) stainless steel with a No. 4 surface finish for window mullions and curved roof panels.

Several factors increased the WCC’s risk of corrosion. First, the surface finish is relatively rough, which increases salt accumulation. Second, there are sheltered areas near the windows, and, finally, there was no provision for manual cleaning to remove the salt deposits and dirt.

Figure A (left) This image shows the building’s original appearance in 1985 and its close proximity to the bay. Photo courtesy of the Nickel Institute.

Figure B (right) This 2008 photo shows the Type 316 stainless steel gleaming in the sun as the result of regular maintenance cleaning. Photographer: Les Boulton, Photo courtesy of the Nickel Institute.

Type 316 stainless steel with a high-quality, smooth surface finish is generally the most cost-effective choice for boldly exposed, long- term coastal applications. It contains 2% molybdenum, which helps to prevent pitting and crevice corrosion caused by salt deposits.

After 23 years of service without maintenance cleaning, the stain- less steel had unattractive corrosion staining. Panel replacement was considered until the Nickel Institute and the New Zealand Stainless Steel Development Association showed building management that cleaning could easily restore the original finish. Figure B shows the building after cleaning in 2006.

The sheltered stainless steel is now cleaned regularly to keep it sparkling. Only a few dented panels were replaced. Douglas Milligan of the WCC stated, “The cladding has basically stood the test of time for over quarter of a century, even perched on the side of a body of salt water.”

Stainless Steel Selection Criteria

Section 1: Environment , Score = 0

The IMOA publication, Which Stainless Steel Should Be Specified for Exterior Applications? provides stainless steel selection assistance. The site and design scores below are based on the guidelines in that brochure. Copies can be downloaded from www.imoa.info or ordered by emailing info@imoa.info.

Wellington has low urban air pollution and particulate levels. The primary sources of pollution are motor vehicles and residential fireplaces. Sulfur dioxide levels are so low that they are not regularly monitored. In addition, strong ocean winds prevent concentration of pollutants along the coast.

Section 2: Coastal Salt Exposure, Score = 4

Recent corrosion research has shown that the greater Wellington area has a very corrosive environment. Moderate to high ocean winds increase the air’s salinity near the water. The building is less than 100 m (328 ft) from the bay and this is a high coastal salt exposure environment.

Wellington has a mild climate with average daily temperatures between 4 and 25ºC (39 to 77ºF). The average annual rainfall is high (1220 mm (48.4 inches)) and frequent heavy, wind-driven rain helps to minimize corrosive deposits on boldly exposed surfaces. The average humidity level is above 60%.

Section 3: Local Weather Pattern, Score = -1

(1220 mm (48.4 inches)) and frequent heavy, wind-driven rain helps to minimize corrosive deposits on boldly exposed surfaces. The average humidity level is above 60%.

Section 4: Design Considerations, Sheltered Score = 2, Exposed Score = 1

The No. 4 polish on the Type 316 stainless steel is rough (just under 1 µm or 40 µin). Rough surface finishes increase salt, pollution and dirt accumulation and the possibility of corrosion. Unsealed crevices and improperly cleaned welds contributed to the previous corrosion problem but these mistakes were corrected. Some of the stainless steel is sheltered from rain washing and this increases the score by an additional point.

Section 5: Maintenance Schedule, Score = -2

The building was not cleaned until 2006. Corrosion staining was evident prior to cleaning, particularly in sheltered areas. The stainless steel is now cleaned quarterly to keep this highly visible building sparkling.

Stainless Steel Selection, Sheltered Total Score = 3, Exposed Total Score = 2

Type 316 stainless steel is appropriate for many coastal applications. It performs best if a good quality, smooth finish is used, and the design takes advantage of rain cleaning. The rougher finish on this project makes more frequent cleaning or a more corrosion resistant stainless steel necessary. Quarterly cleaning of the sheltered stainless steel is necessary to retain the desired sparkling appearance. Based on the score, the panels that are boldly exposed to rain may only need annual cleaning, but the current regime ensures a consistent attractive appearance. This project shows that Type 316 stainless steel can generally be restored to its original appearance with minimal effort.

Acknowledgement: The author would like to acknowledge the assistance of the New Zealand Stainless Steel Development Association (NZSSDA) and the Nickel Institute who provided the information and photos used in this case study.