Latest News

Impeccable finishing and a firm handshake

6 July 2025

What does it take to grow a respected stainless steel fabrication business in New Zealand today? Here, Stainless Works director Boyd Carruthers talks about his company’s road to success.

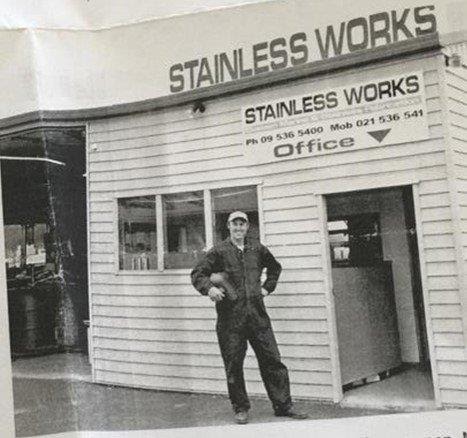

Twenty years ago, Boyd Carruthers and his wife Lian Carruthers started Stainless Works Ltd as a two man band working out of a small marina facility.

Today, Stainless Works has evolved to become a thriving stainless steel fabrication business employing eight highly skilled staff.

The company’s work involves the design, manufacture & installation of custom marine and architectural stainless steel fabrications, with an emphasis on handrails & its unique bespoke balustrades.

Early days

Having served his apprenticeship with NDA Engineering, focussed on F&B-related fabrication, Boyd Carruthers headed overseas where he met Dutch-born Lian, who became his wife.

The pair travelled extensively then returned to New Zealand where Boyd was first exposed to the marine side of stainless steel fabrication, working for McMullen & Wing boatbuilders.

McMullen & Wing, based on the Tamaki River, was building super yachts at the time and as a fabricator Boyd Carruthers became part of that process.

“However, we were living in Beachlands next to Pine Harbour Marina then and there was a boat builder there, and a short time later I went to work for him instead — saving a couple of hours commute a day.”

Timing is everything

It had always been Boyd’s dream to own his own business and soon after that Boyd and Lian took over the lease and started up their own business as Stainless Works Ltd – mainly with marine-related stainless steel fabrication and finishing, and employing just one fabricator.

In these fledgling years, Lian had another full-time job — so it was a case of writing cheques on the kitchen table come evenings.

At this time, in early 2005, the super yacht industry was waning but The America’s Cup had heightened the profile of the high-end marine industry generally — and Stainless Works quickly grew into that space.

Exacting standards and a limited playing field

“There aren’t many of us in the Marine and Architectural industries, and the high level of accuracy demanded when fitting, welding and especially surface finishing required is not easy to achieve,” says the Stainless Works director.

“You have to love perfection to care enough.”

A high level of surface finish is important for two reasons — firstly in the salty environment that yachts are subjected to, the shiny surface finish will ensure that stainless steel performs over time as expected, and secondly a seamless surface finish is essential to maintain the superior aesthetic of luxury vessels.

“Our butt welded joints are typically polished out so that they are undetectable,” says Boyd. “This does make jobs very labour intensive which is reflected in the value of the finished article.”

“The customer has a right to expect perfection.”

Expanding domain

However, marine fabrication is only part of the Stainless Works success story.

“Our biggest growth has been into the architectural stainless steel area,” says Boyd.

“Over the years, beautifully finished stainless steel streetscape elements — handrails, balustrades and the like — have presented relatively high volume for us and that’s really how we’ve grown.”

Today, along with luxury boat owners, Boyd’s customers consist of government departments like the Ministry of Education, architects, developers, quantity surveyors in commercial construction and civil, and also residential builders, homeowners and their interior designers.

An effective website can’t be underestimated

A quick visit to the www.stainlessworks.co.nz website displays the breadth of products designed, fabricated and installed by Boyd and Lian’s team of fresh faced staff.

“Our Website pops straight up on page 1 ‘organically’ with a simple search for stainless steel,” says Boyd.

This has been an important marketing tool for Stainless Works, especially for young quantity surveyors finding their own industry contacts.

The design side of things

“Over the years we have undertaken a lot of design work to make an expensive product more competitive and also to minimise material costs and labour volumes — so we’ve come up with good looking designs that have a point of difference and along the way found out what works,” he says.

“This extensive design work was also driven by the need to meet legal structural and architectural standards of NZBC for balustrades.”

Today, the company creates its own stainless steel fabricated balustrades; plus, for over 11 years has offered services in the quantity surveyor/design role, with full CAD drawing capability as a part of this.

Staff – home grown is best

Of course, a substantial workload necessitates a tight, capable and highly qualified team and Boyd shares some insights on how he has kept on top of this.

“Skilled staff have always been difficult to get — we couldn’t grow for a long time because we just couldn’t get the right staff.”

Historically, Boyd and Lian had used a string of subcontractors with only limited success.

So what Stainless Works has done for the last 15 yrs is to grow its own staff.

“With the help of some grumpy old tradesmen over the years here, we have taken on young people for Work Experience and moved on to offer them apprenticeships.”

“This empowers the old school to teach and impart their knowledge and skills to the new generation,” he says.

“And over the years they’ve stayed with us — so now we have a team of eight highly skilled young tradesmen.”

Level of care

The company’s staff members comprise a pretty close unit, happy in each other’s company socially, they’re like family to Lian and Boyd.

“We take a holistic approach to their health and wellbeing,” Boyd says.

“Nowadays you don’t just employ someone, and they work for you — there is a level of care to make sure there’s a healthy, productive headspace for all.”

“We’ve helped these teenagers mature into fine young men who are buying first houses and having babies!” he says.

“Lian and I are especially proud to germinate real life pathways.”

A powerful brand

So how does a business gain a shining reputation in the stainless steel fabrication industry?

For Stainless Works one key factor is to achieve an extremely high level of product finishing on everything it touches — vital in both the marine and architectural worlds. Another key factor is the human side of things — being highly personable with clients and the company’s network of sub trades.

“In this way, Boyd’s approach to people and business is Stainless Works’ brand,” Lian says.

In fact, it’s an attribute shared by both Boyd and Lian – and one that they pass on to their staff.

“Looking people in the eye and having a good handshake will always stand for a lot — that’s how we operate,” Boyd says. “We do as we say, no corners cut.”

“Plus, reliability – I have always stood by my quotes, good, bad or ugly.”

Voice of the industry

As well as benefitting from the industry, Boyd gives back, too — he has been on the board at NZSSDA for a couple of years and shares his reasons for this.

“Prior to 1999, New Zealand had no formal, technical backup for stainless oriented business, there was no overarching governance of the stainless steel industry to fall back on — so, when the NZSSDA was formed, it was a relief and seemed a great way to network in a previously silent and solo run business world,” he says.

“It’s a good feeling to be able to contribute — to impart some technical knowledge and general know-how to others in the industry, and of course getting to know our allies in business all facing similar challenges.”

“Even today with so much information available online, the NZSSDA brings it all together and enhances it for people like you and I – it’s one place to go to get reliable, applicable information.”

Advice for young businesses

So what’s a good word of advice for a fledgling out-fit just starting up?

“Aiming high with your own quality standards from the get-go is an absolute must, if you expect to attract repeat business,” the co-owner of Stainless Works says.

“If you start off like a rough and ready cowboy, you’re out right away.”